Concept in Definition ABC

Miscellanea / / July 04, 2021

By Javier Navarro, in May. 2017

The machining process refers to the different techniques of industrial transformation of metals. In this sense, it is a process that is part of the metal and mechanics.

The machining process refers to the different techniques of industrial transformation of metals. In this sense, it is a process that is part of the metal and mechanics.

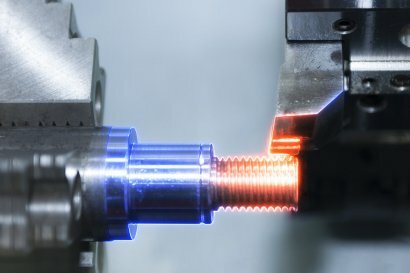

The main idea Machining consists of turning a piece of metal into an industrial part. For this, operations are carried out in which the material is eliminated and modified. Thus, an ingot or a metal bar can be altered using some techniquesuch as chip removal or abrasion. With this system, pieces with all kinds of sizes, shapes and functions are produced.

Different ways of machining a metal

Tools such as parallel lathe, milling machine, turning and electrolytic machining are used to remove chips from metals. The most traditional machine in this sector is the parallel lathe.

Helical machining is a technique designed to manufacture helical shaped objects, such as corkscrews, drills, milling cutters or toothed tools.

Abrasion machining consists of the wear of metal parts that have not been cast, as occurs with the forging of the steel or in some welds.

The history of machining dates back to the stone age

The first stone tools were obtained by carving or polishing and in this way spearheads, ornaments or arrows were made. When the human being left the nomadism and introduced the farming, they began to make utensils through cooking.

In the so-called age of metals, the smelting techniques of metal began, especially copper. It wasn't until industrial Revolution in the eighteenth century when the next leap occurred qualitative in the machining process.

The invention of steam engines and new energies allowed the further development of the steel industry. Despite the undeniable scientific advances, the different machining techniques remain the same: carving, cutting, drilling and turning materials.

On synthesis, the different machines and tools used in machining avoid human effort and allow the creation of all kinds of parts.

On synthesis, the different machines and tools used in machining avoid human effort and allow the creation of all kinds of parts.

A simple screw

Some screws can support several tons of weight, as in the case of metal bridges or wind turbines. Most of them are made from a carbon and reinforced steel alloy and are then heat treated to make them strong materials. Several machining processes are used to get a screw. Among them we can highlight cold forging or filleting to form the thread.

Photos: Fotolia - Andrey Armyagov / Phuchit

Topics in Machining