What are Oil Use Pipeline Products (OCTG)?

Reliability Electric Resistance / / April 02, 2023

Chemical engineer

The OCTG suite, which responds to Oil Country Tubular Goods, includes pipes used to produce well fluids, that is, in oil and gas reservoirs, associated with other components of the drilling system to form the "production string" and thus be able to extract the single-phase, two-phase or even fluid there triphasic

Design standards and features

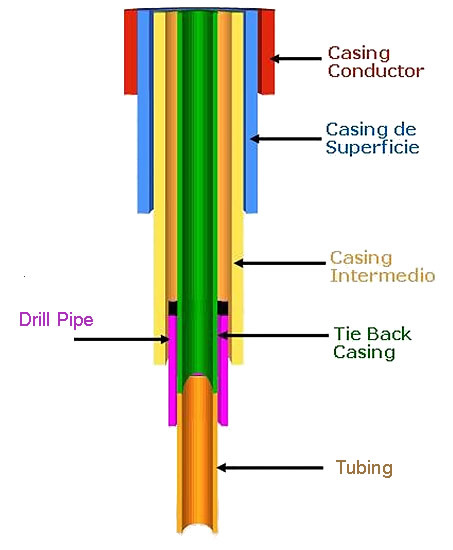

One of the standards that provides guidelines on the design and manufacture of these tubulars is API 5CT and here it is defined as production pipes as the set of three types of pipes: drilling, casing, and production properly. Each of them has a specific function in the extraction task; the first connects the drill collar and allows the first task. Secondly, the casing allows the support of the well during the development of the drilling task and after its completion. Lastly, the production pipeline is the one used for pumping hydrocarbons to the surface. In the oilfield industry, these tubulars have a specific name: the first is “Drill Pipe”, the second is “Steel Casing Pipe” and the third is known as “Tubing”.

These pipes are designed based on the geometry of the well, the type of well, the type of fluid to be transported and allow the conduction of the fluid towards the surface. The production string has the purpose of protecting these pipes against erosion or even corrosion produced by the transported fluid.

Drill pipe is a seamless tube, of considerable size and a diameter large enough to allow the flow of hydrocarbons and water, added in many sand wells. Basically, its main function is to allow fluid to be pumped through the bit and directed through the annular section (space formed between the pipe and the well casing). The design conditions are rigorous due to the tensile stresses and the high internal pressure to which it is submits, so its design standards are governed by the "American Petroleum Institute" in its API 5DP and API codes Spec 7-1.

On the other hand, casing pipes or steel casing pipes or "Casing" are known to be, logically, made of steel manufacturing, which gives it the necessary properties in terms of resistance to stresses, corrosion and structurality of the well. When a well is drilled, it is necessary to contain it, in order to protect the reservoir around it and, mainly, to avoid the contamination of underground aquifers, which is transferred when drilling the well to depths considerable. For this reason, this well must be lined and it is done through this type of pipe, which supports high axial stresses, due to the internal pressure of the fluid that is extracted, but also the external pressure of the cement and the soil itself, since, in order to fix the casing pipe, between the well and said pipe, drilling tasks are carried out. cementation. This cement is subjected to many tests to ensure that the well is able to produce safely, avoiding unexpected control outputs, contamination and collapses.

In other words, the function of this pipe is essential, since it fixes the drilling string avoiding collapses and prevents contamination and loss of fluids, among others. It should be noted that, in general, it is not a single casing that is placed. Depending on the type of well, the quantity is defined, although in general between 4 to 7 different tubulars are placed. Here, too, the API 5CT standard provides for design guidelines and specifications.

Finally, the "Tubing" or production pipe is placed inside the casing pipe and is the one who has direct contact with the fluid that is extracted. It is of the simpler type of design than the other two, however one must consider what type of fluid is removed. These pipes support the internal pressure generated by pumping to the surface and follow the API 5CT standards.

To better understand the location of each of them inside the well, you can see the following image: